Newly launched this year by the Italian Company, the Sigalsub Nemesis HT, which stands for High Technology, has won the Best Choice in the Roller-Inverter-Vela category. It all starts from the excellent base of the Nemesis (finalist in the 100-200 € category with the aluminium barrel version, and winner in the above 200€ with the Carbon barrel version).

Power system

Its designer, Riccardo Iacovacci, also the mind behind the design and manufacturing of the successful Sigalsub Nemesis, does not want to talk about an inverter system, but indeed we can take such solution as reference when talking about the power system of the Sigalsub Nemesis HT. Depending on the length of the barrel, one or two couples of straight 16 mm Sigalsub Extreme elastic bands are hooked to the inferior part of the handle, that Iacovacci had designed already with the launch of the standard Nemesis. He indeed from the start considered the possible evolutions of such great speargun in its Roller and “Inverter” versions. A third couple of 16 mm Sigalsub Extreme elastic bands is connected laterally to the barrel, just in front of the handle thanks to two small “mushrooms”. The latter are extremely neat, with a radiused base that perfectly matches the profile of the barrel.

The three couples of elastic bands are then connected to two pulleys, one per side, which are themselves connected to two lines reaching the rollers on the muzzle and then closing together as a wishbone.

Muzzle

The muzzle is one of the amazing pieces of art of the Sigalsub Nemesis HT. It design permits to have an extremely reduced weight and a compact shape. It is made of glass loaded Nylon, but the % is not too high to be able to keep the smoothness of the surface of the material and so permit a good slide of the lines connected to the elastic bands.

The structure

The structure is great. It has a rigid strong part in the upper surface and near the holes where the line passes through. This gives the muzzle an amazing strength. At the same time the central 8 mm diameter steel axle on which the two rollers rotate gives great transversal rigidity. The remaining parts of the glass loaded Nylon muzzle are thin enough to reduce the weight and elastic enough to bend but not to break.

Rollers

Sigalsub has worked a lot to choose the best rollers which could give great performance with excellent weight reduction. The rollers are made in POM, Polyoxymethylene, also known as acetal, polyacetal, and polyformaldehyde. It is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. Also a central axle, positioned between the steel axle and the roller, is made of POM. Such element is cleverly designed with +5 tenths of a mm more than the thickness of the rollers, so the latter are always free to rotate without friction on the lateral walls of the muzzle.

Pulleys

The pulleys are also made in Sigalsub, which means Made in Italy. They are specifically designed for the need of this new amazing speargun. The pulleys are made of two steel plates connected with two steel axles. On one of the two axles, on the side facing the handle, are connected the three couples of rubber bands. On the other one a POM roller is mounted, on which the line going all the way to the muzzle passes through. The steel axles can be dismantled with an Allen Screw. The positioning of the pulleys must be correctly done by passing the loops of the lines of the rubber bands in the right way so the pulleys are parallel to the barrel and do not rub on it, so avoiding to scratch it.

Loading

The loading of such an “Inverted” like speargun of course is more complicated than the traditional single or double circula band ones, but the power released is extremely higher. The loading action starts with the two couples of elastic bands disconnected from the inferior part of the handle.

Without needing a loading tool, the spearo can easily take hold of the loop connected to the wishbone and pull it all the way down along the shaft, hooking the wishbone on the shark fin he prefers.

After this, the Sigalsub Nemesis HT can be turned upside down and a first couple of rubber bands can be hooked. In the final version of the Nemesis HT the first couple to be hooked is the one with the line in black colour. The final couple of rubber bands has a white line to be hooked under the handle (just on top of the reel). The Nemesis HT can then be turned back in the right position and the upper bands can be hooked to the last shark fin.

Lenghts, versions and setups

Lengths

The Sigalsub Nemesis HT is offered in 5 lengths, 76, 82, 92, 104 and 116 cm. The barrel can be the standard aluminium version, or the exclusive carbon fiber one.

Elastic bands

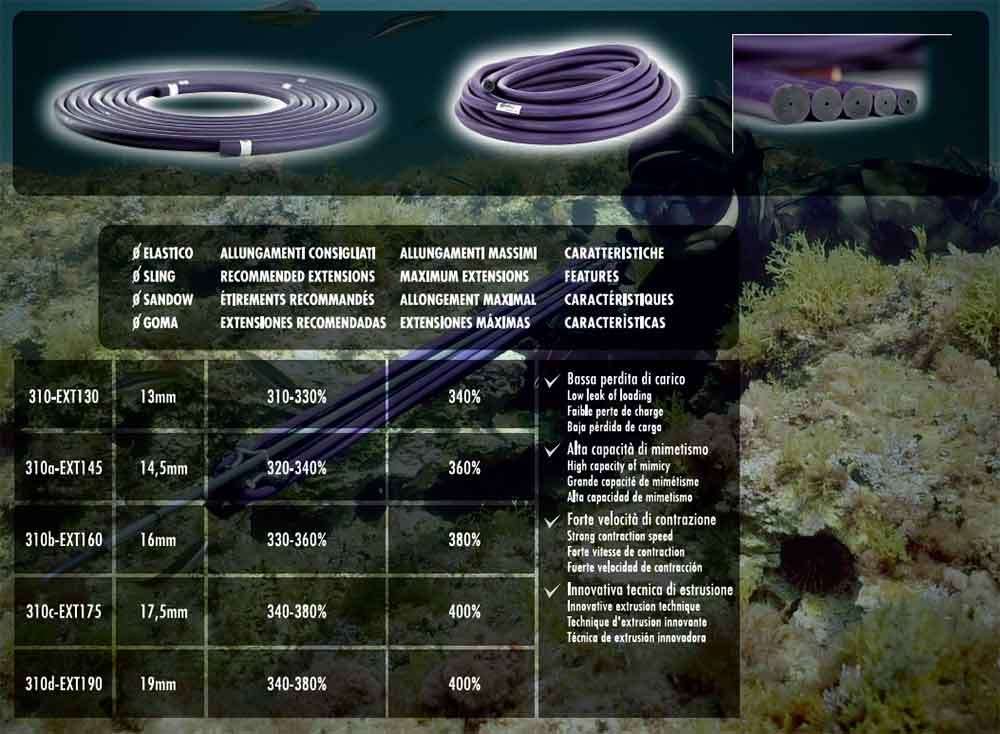

The elastic bands are the Sigalsub Extreme. They are two pairs of 16 mm diameter bands for the 76 cm aluminium version, while the carbon fiber has one pair of 16 mm and one pair pre-tensioned 17.5 mm diameter. The 82 cm version has been tuned with one pair of 16 mm and one pretensioned of 17.5 mm pairs of elastic bands on the aluminium version and two pairs of 17.5 mm elastic bands for the carbon fiber barrel solution. Moving to the 92 cm and longer versions, the pairs of rubber bands become three, one pretensioned an two to be connected undert he handle. On the aluminium versions all the elastic bands are 16 mm of diameter. On the carbon fiber barrel solutions, the pretensioned pair of rubber bands is 17.5 mm diameter, while the two other pairs are 16 mm.

Shafts

The shaft is a 6.5 mm diameter HRC for all the lengths of the aluminium barrel version, and the same shaft with 7 mm diameter for the carbon fiber one.