Pedemonte is an Italian Company based in Liguria, which is the base of the most important diving companies in the world, and is expert in the design and production of what are among the most high quality and performing tailor made bike frames, but also automotive components for motorsports.

All this amazing know-how in the carbon fiber components design and manufacturing, starting from 1970, makes Pedemonte an amazing Made in Italy firm, with unbeatable expertise in the sector. All this professionality is now available also in the freediving and spearfishing sectors, where Pedemonte launches Pedemonte fins, with their Apnea model. But first, let us tell you about our visit at Pedemonte Headquarters.

Top end machinery for carbon fiber

Big dimensions Autoclave

The manufacturing process which is today considered the best possible to obtain the top quality and performance carbon fiber components is lamination in moulds in autoclave. Pedemonte has already, due to the high quality and performance needs requested by the bike and automotive worlds, a top standards autoclave of big dimensions. The fins are positioned first in carbon fiber moulds which guarantee even better thermal and dimensional precision and consistency. After that, they are put into the autoclave at controlled temperature and very high pressure. This is how the Pedemonte Apnea fins, thought both for CWT and spearfishing, are made. These are the fins we will soon present and test.

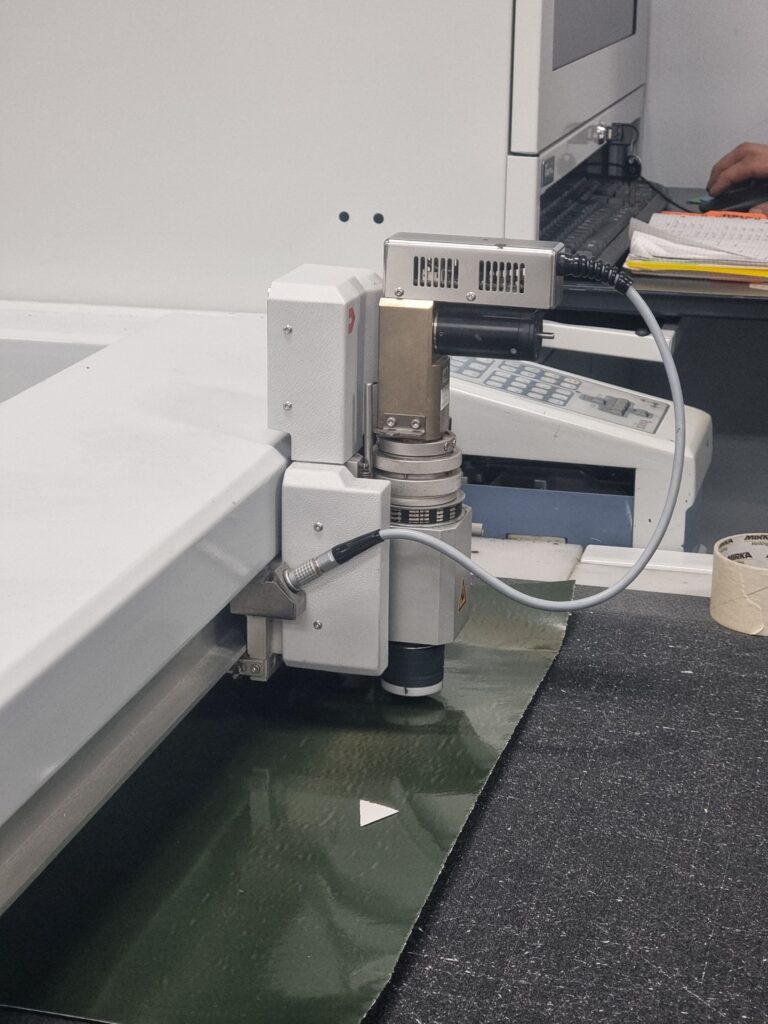

Floating plotter

The perfect dimensional cut of each blade is ensured by a floating plotter, which adapts perfectly to the surface of the carbon fiber thanks to the controlled mobility of the floating support.

High monitored quality carbon fiber

Pedemonte has already strong contacts and commercial relations with the best carbon fiber producers for bike frames, and thanks to this the Italian Company is able to select the best materials also for freediving fins. Pedemonte utilized Prepreg carbon fiber to have the most constant and repeatable results for each balde.

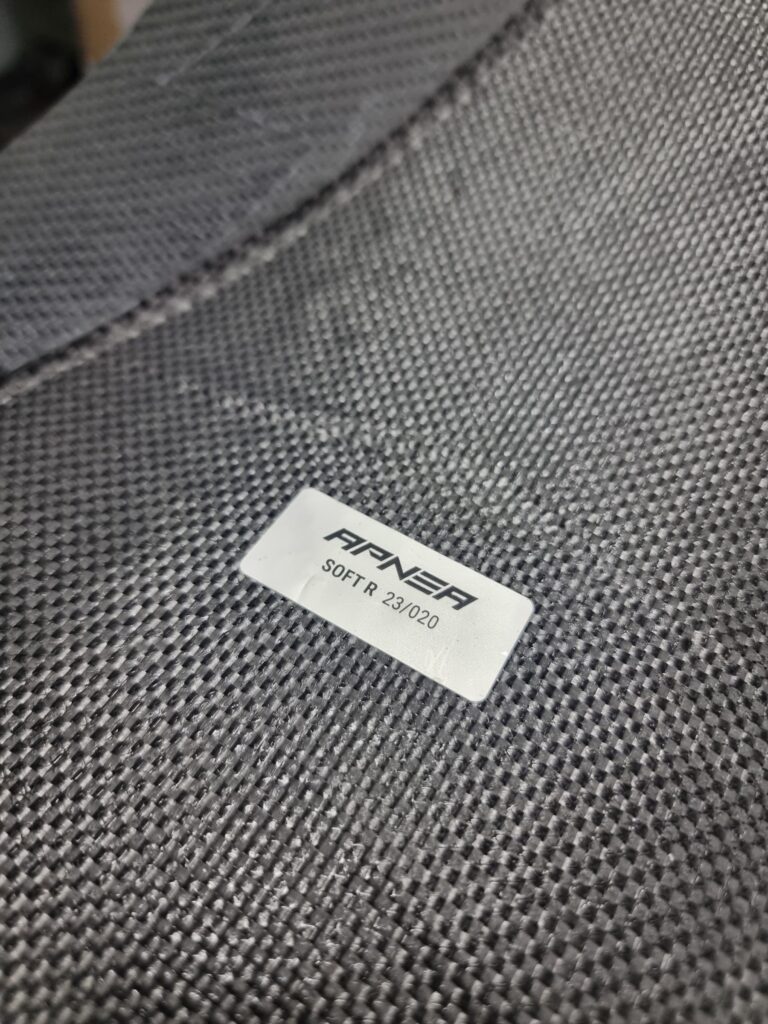

Additionally, the blades are always made from the same sheet of carbon fiber and positioned together in the autoclave. This ensures the same characteristics of performance to each of the two blades of a pair. The carbon fiber sheet is numbered, and the code is printed under each blade, so any quality control can be done tracing back to the batch of material.